Empowering Industries with Precision: A&M EDM Ltd's Journey from Sodick Wirecut EDM in 2002 to Cutting-Edge Technology Across Aerospace, Motorsport, Automotive, and Beyond.

A&M EDM Ltd is an engineering solutions company always striving to maximise its service to clients in the aerospace, motorsport, automotive, marine, medical, rail, defence and general subcontract sectors. To achieve this, the West Midlands company has invested in a diverse range of technology that spans from 3, 4 and 5-axis machine tools and laser welding to laser calibration and more. However, the foundations of the company stem back to its 2002 inception where it all started with a Sodick wire EDM machine from Sodi-Tech.

Wind forward more than 20 years and the Smethwick manufacturer has upward of 60 machine tools with 36 of those supplied by Sodi-Tech. This includes a complete selection of Sodick wire and die-sink EDM machines, EDM hole drilling and high-speed machining centres. Like many subcontract manufacturers, A&M EDM machines a variety of materials that include stainless steel, mild steel, aluminium, inconel, titanium and exotics with a variety of production demands from bespoke one-offs and short runs through to longer run batches for its customers – but one thing that has remained a constant from day one is the technology and support from Sodi-Tech.

A&M EDM Ltd Owner and Managing Director Mark Wingfield says: “My relationship with Sodi-Tech dates way back to the very start. At the moment, we have 36 Sodick machines and this includes a complete variety of machines. A&M EDM specialises in lots of products. We make everything from parts that go into the ocean to parts that go to Mars. The machines have to be reliable because of the accuracy of the work we do. When you spend so much money on machine tools, you want the machines to last. The Sodick machines are very reliable and rarely break down - if you look after the machines, they will look after you. Having used other machines as well as Sodick machines, I always felt that Sodick are the best machines for me. The brand has made this business what it is today. We have taken this business from two people up to 78 people working here. So, I can only speak very highly of the machines, you really are paying for the best kit on the market.”

Adding to this, Lee Finch, Production Director at A&M EDM says: “We offer next day turnaround and if the machines are not running efficiently, or running overnight as we planned them to, we simply cannot offer that service. What I love about the Sodick machines is how user-friendly they are. You can get jobs up and cutting very quickly without having to go into any extensive technical depth with the machine. However, there is the facility for advanced technical operation in the background, but if you just want a quick fix where you can get the machine up and running for a quick turnaround job, the machines are so easy to operate.”

Over the years the company has acquired everything from the AQ537L, AQ750L, AQ750LH and AQ900L through to the AG60L, AG80L, AG100L, AQ35L, AL60G and the most recent ALC600G.

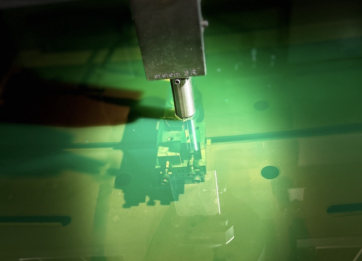

Looking at the latest ALC600G machine that is just been installed, Lee Finch continues: “This machine offers us a new facility where we can ‘turn and burn’ using full 8-axis controlling. When we are looking in the market for new machinery, myself and the other directors at AM& will evaluate what we are looking for and what we are trying to offer to our customers. We also need to identify how our business is going to get the benefit from that purchase. The more advanced technology that Sodi-Tech can offer, then there is more technology that we can offer to offer our customers - and this is how we have arrived at this 8-axis ‘turn and burn’ machine. It gives us the facility to offer a new service to the market.”

Sodick’s ALC600G range of machines that are referred to as ‘turn and burn’ comes with a new standard – the ‘i Groove’ edition with a wire rotation mechanism. This patented innovation rotates the wire during the skim-cut operation so that workpieces are machined from top to bottom with the ‘unconsumed’ surface of the wire. Conventionally, wire electrodes are controlled solely by tension and running speed, while being constrained by a die. Sodick’s i Groove rotation mechanism provides additional control over the wire, resulting in increased surface quality and improved geometric accuracy, whilst at the same time minimising wire consumption.

From a specification perspective, the machine incorporates linear motors and absolute precision linear scales in the X, Y, U and V axes with an X, Y and Z axis travel of 600 by 400 by 350mm and a U and V axis movement of 150 by 150mm. With a maximum wire speed of 420mm/sec that cuts with speed and precision in a 1050 by 710mm work tank, the ALC600G is a precision high-speed performer with a compact footprint to suit any machine shop.

A&M EDM's Journey with Sodick Precision Wire-cut EDMs and Beyond

A&M EDM at its best with 20 Years of Partnership with Sodi-Tech EDM | Together Delivering Excellence in Precision Engineering