Efficiency and precision in manufacturing are more than just goals – they’re the benchmarks of excellence. Sodick's range of Electrical Discharge Machining (EDM) technologies, encompassing Die Sinking EDM, Precision Wire EDM, and Hole Drilling EDM, are designed to meet these benchmarks.

In this article, we’ll look at:

- How Sodick's Die Sinking EDM optimises manufacturing processes

- How Wire EDM and Hole Drilling EDM by Sodick enhance precision and efficiency

- The tangible impacts these technologies have on the manufacturing floor

Join us as we explore how Sodick’s EDM solutions are not just tools, but partners in redefining manufacturing efficiency and precision.

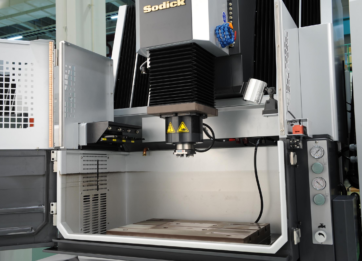

Sodick's Die Sinking EDM

Sodick's Die Sinking EDM machines bring a unique blend of innovation and functionality to manufacturing, setting new standards in accurate manufacturing. Let’s explore the distinctive features that set them apart:

Energy efficiency

Sodick's Die Sinking EDM machines are designed with energy efficiency in mind. This not only reduces operational costs but also aligns with sustainable manufacturing practices, a growing concern in many industries.

Efficient electrode wear management

One of the key challenges in die sinking EDM is managing electrode wear. Sodick's machines tackle this with advanced wear compensation technologies. This not only ensures consistent accuracy over longer production runs, but also reduces the need for frequent electrode replacements, enhancing overall efficiency.

Optimised machining speeds

Sodick has engineered its Die Sinking EDM machines to optimise machining speeds without sacrificing precision. This means faster turnaround times for projects, a crucial factor in meeting tight production schedules and increasing throughput.

Thermal stability for consistent accuracy

Sodick's Die Sinking EDM machines are built to maintain consistent temperatures during operation, ensuring ongoing accuracy and preventing material distortion, a vital factor in high-precision tasks.

Integrated automation potential

Automation is key to enhancing efficiency, and these machines are designed to integrate seamlessly with automated systems. This capability allows for unattended operation, increasing productivity and reducing labour costs.

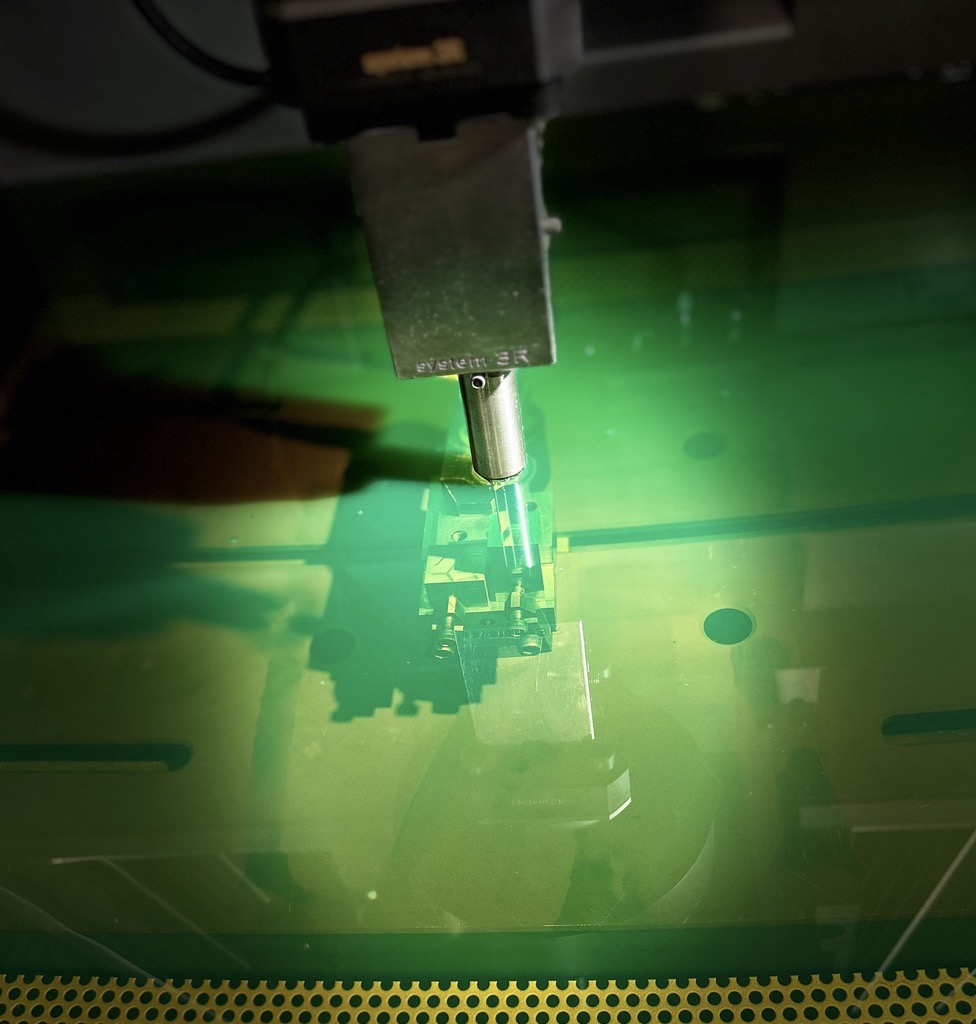

Sodick's Precision Wire EDM Technology

Sodick's Precision Wire EDM technology is a blend of precision, innovation, and efficiency, making it a key requirement in modern manufacturing environments where accuracy is paramount:

Precision redefined

Equipped with cutting-edge features like automatic wire threading and advanced power supply systems, these machines aren't just cutting material; they're crafting with precision, producing superior surface finishes, which are essential for components where even a micron's deviation matters.

Efficiency in every detail

Designed to minimise cycle times, these machines boast sophisticated control systems that streamline the machining process, ensuring rapid production without compromising on the intricate details; essential in aerospace and specialised engineering fields.

Reliability at its core

Sodick’s Precision Wire EDM machines are built to last, renowned for their pillars of reliability and consistent performance, minimising downtime with their ease of maintenance. This reliability isn't just a feature; it's a promise of uninterrupted productivity.

Sodick's hole drilling EDM

When you need fast and versatile machining, Sodick’s Hole Drilling EDM machines offer efficient solutions for specialised manufacturing tasks where precision and rapid processing are crucial:

- The art of precision drilling: Sodick’s Hole Drilling EDM machines are like skilled artisans, capable of rapidly drilling extremely fine holes, with diameters as small as 0.30 mm, at high speeds and with impeccable precision. Ideal for specialised tasks such as creating cooling holes in turbine blades or start holes for Wire EDM operations.

- Material adaptability: Sodick’s Hole Drilling EDM machines are adept at handling a wide range of conductive materials, from hardened steel to exotic metals, making them invaluable in sectors like energy and automotive, where material versatility is key.

- Enhanced productivity: Designed to optimise cycle times, these machines are more than just fast – they are productivity enhancers. Their user-friendly operation and maintenance reduce bottlenecks, ensuring production lines keep moving swiftly and smoothly.

Case studies: Sodick EDMs in action

Why just tell you about Sodick EDM technology, when we can show you real-world examples, demonstrating the versatility and precision of our technology across different industries and applications, highlighting its capability to deliver high-quality, accurate machining for complex and intricate components:

Okugi Manufacturing Y.K

OKUGI Co. Ltd. of Higashikurume City, Tokyo, is a metal processing company that specialises in wire-cut electrical discharge machining. They employ Sodick's oil-type wire-cut electrical discharge machines, which use ultra-fine wires for high precision, offering better surface accuracy and finishing dimensions compared to water-type EDMs.

This specialisation in ultra-precision machining has allowed OKUGI to excel in creating components with extremely tight tolerances and complex geometries, such as waveguides with precise square holes within round holes.

Die Makers Manufacturing

A long-term user of Sodick Wire EDMs, Die Makers has partnered with Sodick since 1996. They have consistently updated their machines to take advantage of advancements in technology, such as better threading, finishing, and accuracy.

One particularly valued feature is the automatic threaders in the machines, which allow for overnight production, leading to cost savings and increased efficiency. The reliability and accuracy of Sodick's machines have been crucial for Die Makers’ operations in the competitive tool and die manufacturing industry.

Discover the future of manufacturing with Sodick EU’s EDM solutions

You've seen the extraordinary capabilities of Sodick's EDM technology and how it's transforming industries, from intricate aerospace components to precision medical devices. Now, it's time to bring this efficiency and precision to your manufacturing floor.

Imagine the possibilities with Sodick’s advanced Die Sinking, Wire EDM, and Hole Drilling technologies enhancing your production capabilities. Whether it’s achieving the finest details or maximising productivity, Sodick EU has the solution tailored for your needs.

Don't just read about the change; be the change. Take the first step towards redefining efficiency and precision in your operations – contact Sodick today and unlock a new level of manufacturing excellence.